Robots

Main text

MZ Medium Payload Robot MZ35F/50F/70F/50LF

|

Lightweight and slim body

Hollow wrist

High speed and High precision

|

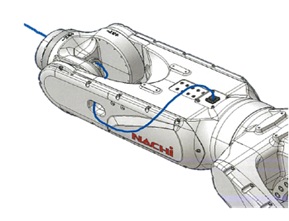

Lightweight and slim body

The lighter weight of the main unit (body weight compared to conventional models: -5%) and compactness (installation area compared to conventional models: -23%) makes it easier to consider peripheral equipment.

7 equivalent for the main body is standard specification, expanding the range of applications.

It can be used with confidence even in harsh environments where chips and coolant are scattered.

| Our conventional machine | MZ medium payload | Conventional model comparison | |

| Robot weight | 640kg | 608kg | -5% |

| Installation area | 286.4 thousand mm2 | 220.5 thousand mm2 | -23% |

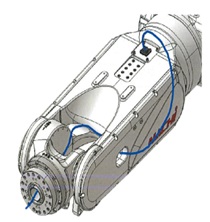

ˇApplication examples

Polishing, Deburring

Bad condition

where cutting chips are splashing

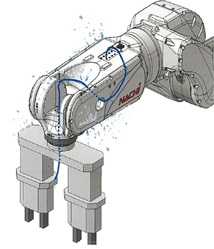

Machine loading

Bad condition

where coolant is splashing

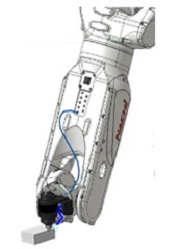

Hollow wrist

Interference is avoided by routing wiring through the hollow wrist.

Flexible operation even in narrow spaces.

High speed and High precision

The high-rigidity design improves operating speed and position repeatability compared to previous models.

Contributes to improved productivity.

| Our conventional machine | MZ medium payload | ||

| Maximum Velocity | J1 | 180°/s | 185°/s |

| J2 | 180°/s | 180°/s | |

| J3 | 180°/s | 185°/s | |

| J4 | 255°/s | 260°/s | |

| J5 | 255°/s | 260°/s | |

| J6 | 370°/s | 370°/s | |